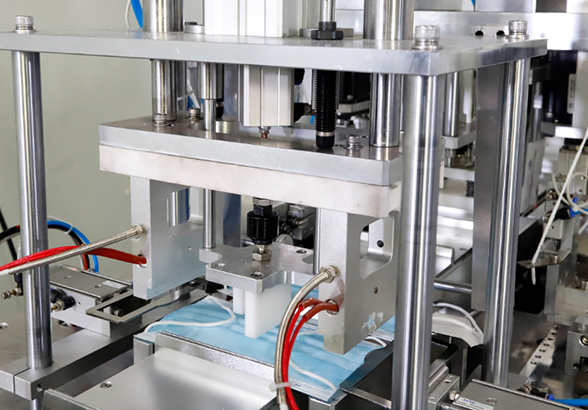

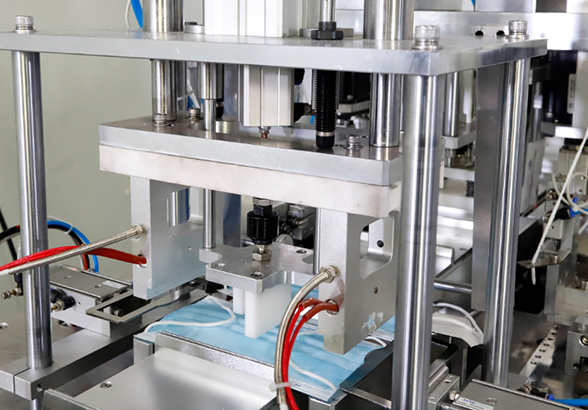

Automatic disposable mask making 1+2 machine line

1. Equipment overview:

This machine is mainly used for automatic forming of disposable masks:

After the whole roll of fabric is unwound, it is driven by a roller, and the fabric is automatically folded and wrapped;

The nose bar is pulled and unwound in a full roll, cut into a fixed length and then sent into the edging fabric, the two sides are ultrasonically welded to the seal, and then passed through the ultrasonic side seal, and then shaped by a cutting knife;

The mask is transported to the welding station of the two mask ear straps through the assembly line, and the final mask is formed by ultrasonic welding. After the mask is made, it is sent to the automatic folding section of the ear straps and folded automatically, and then transferred to the flat belt line for collection for the final packing.

2. Parameters

1) Equipment size: 6800mm (L) × 3600mm (W) × 1900mm (H)

2) Equipment weight: ≤1500kg, ground load> 300KG / M²;

3) Working power supply: equipment 220VAC ± 5%, 60hz, rated power about 6.5-8.5kW

4) Compressed air: 0.5 ~ 0.7MPa, the flow rate is about 300L / min;

5) Use environment: temperature 10 ~ 35 ℃, humidity 5-35% HR, no flammable, corrosive gas, no dust (cleanness is not less than 100,000)

3. Features

1) Can put 3 ~ 4 layers of fabric into the equipment at the same time

2) Using ultrasonic technology, the surface layer, filter layer and bottom layer are automatically bonded. Then automatically press the crease of the outlet cover, trim, shape and cut.

3) Through the conveyor system, it is automatically assigned to the left and right 2 sides.

4) At the same time, through the photoelectric detection, the ultrasonic cutting and spot welding of the elastic straps are firmly fixed in the mask.

5) With full-automatic output function, it realizes full-line automatic operation from feeding to finished products, with an efficiency of up to 100,000pcs/day, which is helpful for the transformation and upgrading of intelligent production of masks.

6) Automatically fold mask ear straps, which can be packed into bags without manual labor folding straps.

7) Equipment production pass rate: 98-99%

4. Configuration:

1) 7 inch touch screen: Xinjie (THINGET) brand

2) Servo motor: 2pcs Delta brand

3) Frequency converter: TECO brand

4) Stepper motor: 4pcs Just Motion Control brand

5) Electrical parts: Schneider brand

6) Pneumatic components: Festo / Taiwan MINDMAN / AirTAC brand

7) Ultrasonic Intelligence: Conprofe Brand

8) System: Xinjie (THINGET) + independent R&D program + encoder Delta brand

5. Leading time

Ready Stock 7-10 Days

6. How many masks can make in one day?

-100,000pcs/24h.

7. How long is the warranty?

-1 year.

8. Machine size

Cutting Machine: 3112*1112*1846mm 6.388CBM

Flipping Machine: 1712*1112*1651mm 3.143CBM

Welding Machine①: 2212*1152*1526mm 3.889CBM

Welding Machine②: 2212*1152*1526mm 3.889CBM

1+2 total 17.3CBM

Fabric Holder

Fabric Holder Ultrasonic & Cutter

Ultrasonic & Cutter 1 for 2

1 for 2 Ultrasonic Welding

Ultrasonic Welding Automatically Fold

Automatically Fold Final Packing Directly

Final Packing Directly

Website: http://www.stcyjx.cn/

Alibaba: https://gdcykj.en.alibaba.com

Cell Phone/ WhatsApp/ Wechat: 86-13790877527

Fax: +86-754-82200365

Sales Manager: Joe

Add: 2-02C2 Yiying Science and Technology Industrial Park,

Xiashan Town, Chaonan District, Shantou City, Guangdong, China, Zip: 515144