Automatic Toothbrush Blister Labeling & Packaging Machine

Introduction: This equipment is suitable for packing daily produts, stationery, hardware, cosmetics, medicine and other blister packaging.Packaging such as: toothbrushs, pens, solid glue, lip balm, pen, glue, socket, bearing, brake pads, injections and other packaging, so as to improve the grade of products

Model: BZJ-B3

Size: 3850 x 1100 x 1800(mm)

Weight: 2500Kg

Product feature

Based on former toothbrush packaging technology from Korea Xinya and Germany, our researchers took the initiative to develop a new type of Automatic Toothbrush Blister Labeling & Packaging Machine, combining with the new toothbrush in the market.

Comprised of automatic paper setting, thermal synthesis technology and punching shear, this machine applies full servo double CAM spindle muscle, Two-stage servo chain tension membrane institutions as well as precise Servo labeling, enjoying high-tech imported NC coding and PLC programmable logic, which gives this new machine an edge in high efficiency, high stability high adjustability, low cost of molding, convenient replacement, low wear, low noise level and so on.

This machine has been obtained a number of national technical invention patents.

Product specification

.jpg)

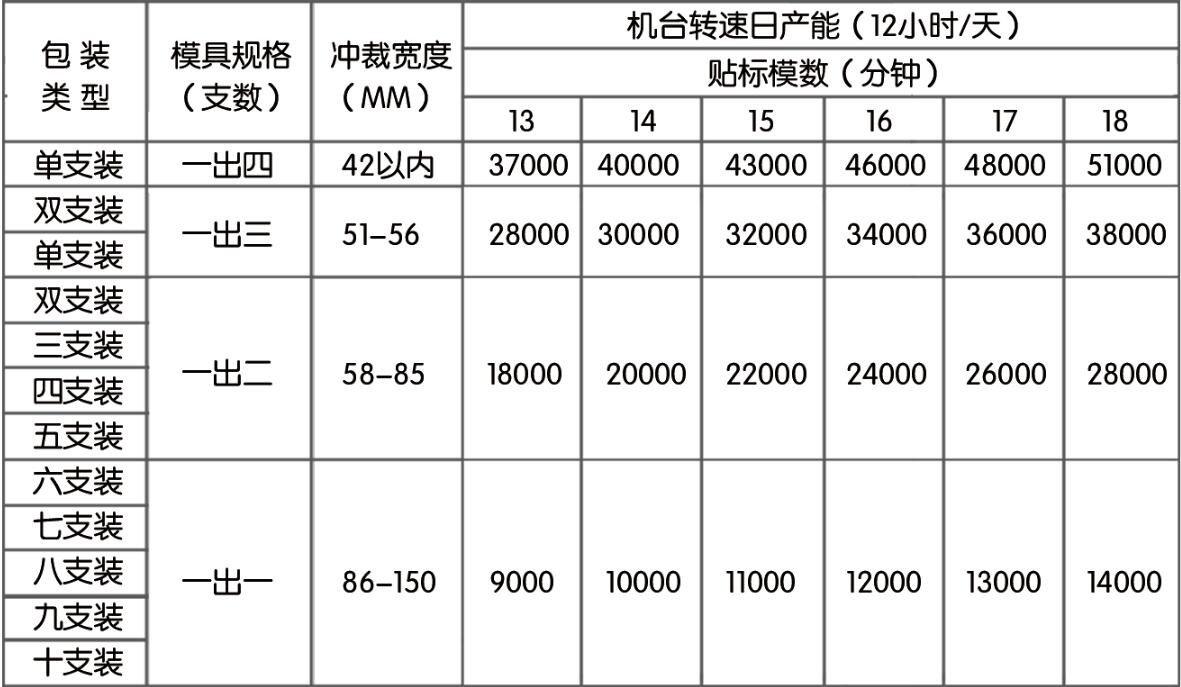

Packaging machine capacity table

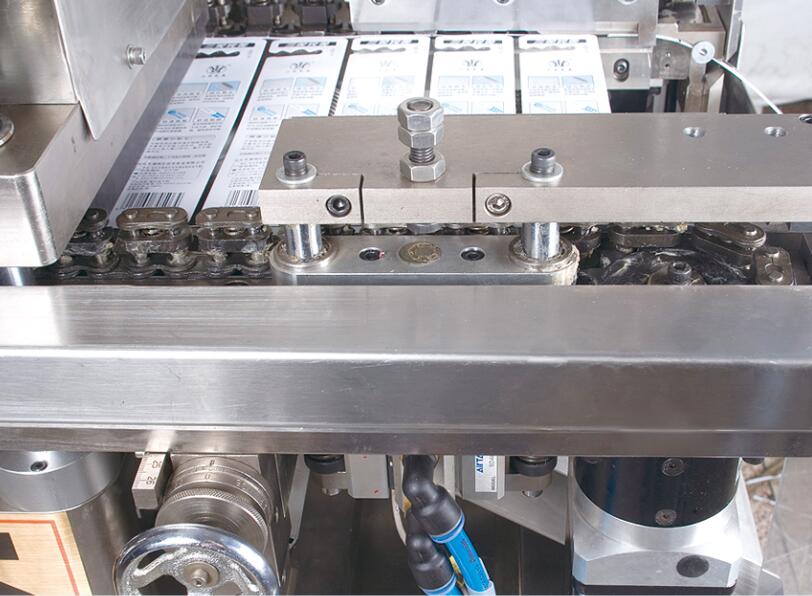

一、主轴部分 Spindle part

.jpg)

Principle: adopting servo drive and double cam shaft.

Features:

1. high accuracy of the die simultaneous localization

2. large torque force (maximum torque of 40000kgm), high stability, low wear and low noise.

二、拉膜部分 Film-drawing part

Principle: adopting servo drive chain to clip the film-drawing.

Features: smooth accuracy of film-drawing localization with tolerance reaching ± 0.2MM, high adjustability of stroke and filming without paste

三、吸塑部分 Blister part

Principle: adopting pneumatic slider position

Features: adopting exact depth positioning of blister forming, compact structure, low air consumption and easy replacement of the die.

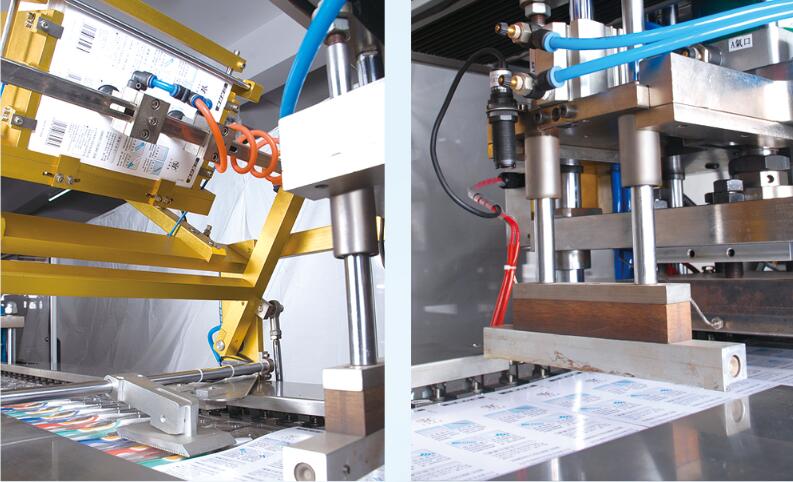

四、热合部分 Heat-sealed part

.jpg)

Principle: adopting cylinder type with adjustable liquid pressurization,

Features: good effect of seal and paste, good flatness, high efficiency, strong adjustability of thickness of paper card.

五、冲剪部分 Punching part

Principle: adopting double cam with soft cutting and punching shear

Features:

1.low cost of punching die, easy replacement, small blanking force and low noise.

2.Functions work position and product specifications with adjustable scale ruler

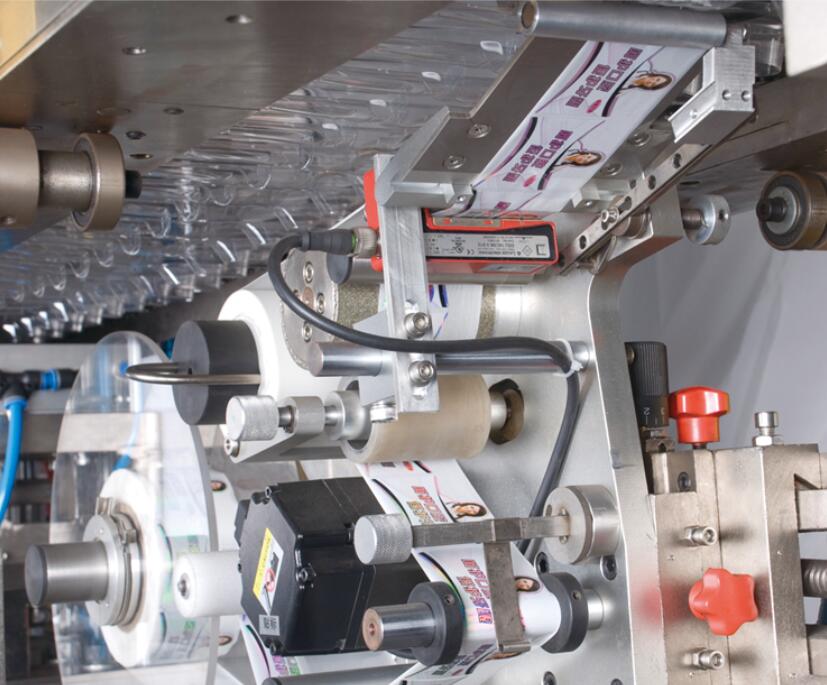

六、贴标部分 Labeling part

Principle: adopting roller of servo drive for against labeling.

Features: high smooth accuracy of label positioning, strong adjustability of three-axis and simple operation of exchanging the label.

七、切边排料部分 Part of the layout of trimming

Principle: adopting automatic layout of trimming material.

Features:

1. simple operation, small occupation space, high efficiency, low downtime rate, strong adjustability and automatic cutout without manual work.

2. Functionality increasing is on basis of the equipment of automatic plug-in card.

八、放纸部分 Paper Feeding

Principle: adopting special scan to detect.

Features:

1. high resolution of front and back of the paper card not to cause

the heat-sealing sticky on the die.

2. Separable function of multilayer paper not to cause double layers paper.

九、真空、汽、油路部分 Parts of vacuum and gas circuit adopt the principle of imported cylinder

Principle: solenoid valve, vacuum pump with oil-free.Automatic lubricating oil supply system

Features: strong stability, high frequency of use, long service life,smokeless, low noise, large vacuum force, high security, suitable for the use in environmental protection workshop.

十、电路部分 Circuit part

adopting the principle of speed servo adjusting, operation control mode with imported PLC programmable touch screen and digital display of the heating module.