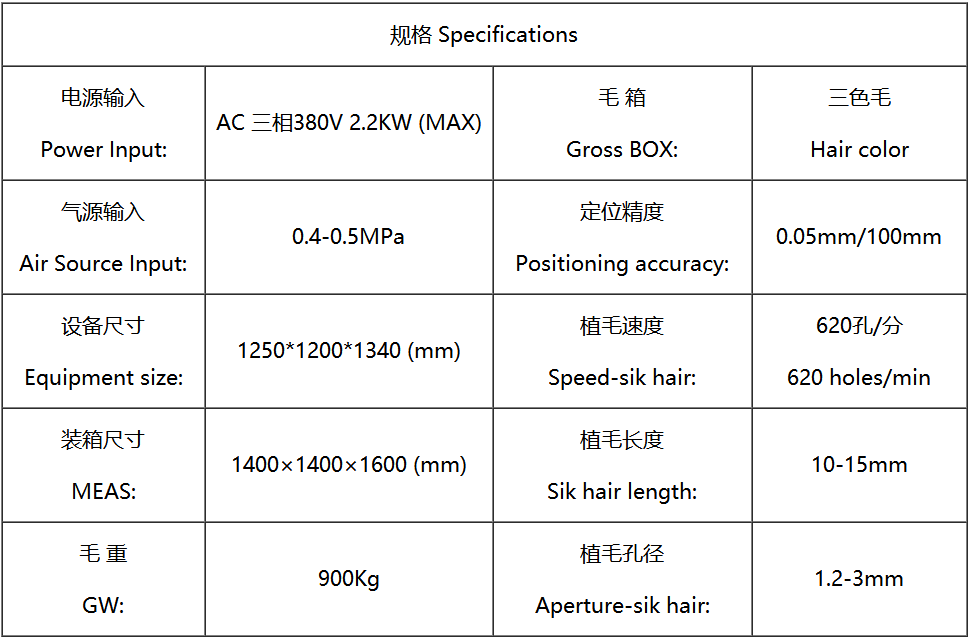

High-speed intelligent digital Tufting machine (special-shaped hole tricolor)

Introduction: 1. produce square hole type brush, conventional brush more versatile 2. Adjustable mechanical structure design, convenient and quick adjustment.

Model: AH9ZFP-C3

Size: 1250 x 1200 x 1340(mm)

Weight: 750Kg

Features

First, the introduction of the German CNC technology research and development of automatic intelligent CNC scanning hole coordinates touch screen LCD computer

Second, the use of Japan's Fuji Five-axis original servo motor, high-performance spindle servo motor

Third, decoration hair device to reduce hair repair process

Fourth, the upper and lower hair removal device can produce the inner flat outer sharp product

Fifth, the whole machine adopts Germany imported INA, AFG, DURBAL and Japan NSK, IKO and other brand bearings

Sixth, the use of Germany FESTO valve and hair box pressure part of the British ORIGA rodless cylinder

Seventh, universal fixture can rotate 180 degrees plus or minus 180 degrees and universal shaped handle box, nylon rolling handle bucket

VIII. Full-closed-loop system has strong stability, high repeat positioning accuracy, easy operation, and strong anti-interference ability

.jpg)

First, intelligent CNC computer part

Features: 1. The introduction of German CNC numerical control technology research and development intelligent scanning aperture coordinates key LCD computer

2, using the United States imported CNC CPU chip, speed P4 dual-core

3, automatic tracking speed

4, accurate positioning, easy operation

5, the system is stable and reliable, adapt to different environments

6, full closed-loop system, strong anti-interference ability

7, can be upgraded to the highest number of hairy holes 99 holes (additional options)

8, can be upgraded to install the upper and lower hair splitter (additional options)

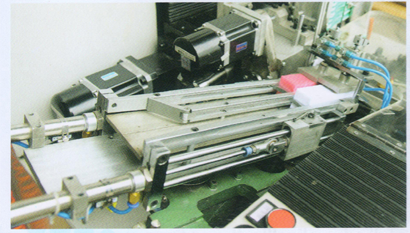

Second, the table, handle servo motor part

Features: 1, X, Y axis table, slewing using imported Japanese high-precision servo motor

2, the use of German imports of precision C1 double threaded ball screw

3, rapid displacement: 620 holes / minute, jump hole distance can reach 8-10mm

4, more flexible and reliable rigidity

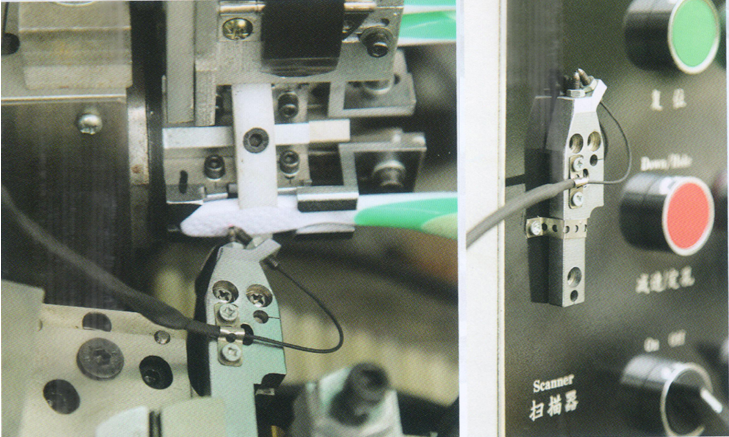

Third, automatic scanning hole coordinates part

Features: 1, using high-tech infrared automatic scanning handle coordinates

2, high efficiency of changing products: 40 holes about 5 minutes

3, high precision positioning coordinates: tolerance ± 0.02m

4, easy to operate, fast, easy to learn

5, reduce the cumbersome tuning steps: manual measurement of pitch precision precision fine-tuning

.png)

Fourth, high-speed hair planting

Features: 1, the introduction of German technology research and development fixture

2, using imported German materials to produce hair, take hair knife, hair shaft

3, implanted hair, hair rod, high precision mirror spark technology through the import of vacuum processing technology: high hardness, good toughness, strong wear resistance

4、Framing machine high-precision machining process error value ±0.01mm, implanted hair diameter :1.2-3.0mm

5, hair growth stability, high efficiency, strong pull, not scattered hair

Five, two-color hair box

Features: 1, quoted the German technology cylinder automatic circulation effect of pressure principle: uniform pressure, high adjustability

2, using dual-hair cylinder to adjust the hair

3, color change using Japanese original servo motor, can support two holes for a color

4, using electronic control plus hair technology, easy operation, fast

5, hair knife hair high stability, not thin hair, no hair

.png)

Sixth, nylon rolling handle bucket part

Features: 1. Add decoration hair device to reduce hair removal process

2 easy to glue brush

Handle removal