High-speed intelligent CNC flocking machine (in normal two-color configuration)

Introduction: The whole machine is made up of imported IMA, AFG, DURBAL and Japan NSK, IKO and other brand bearings. Fully closed-loop system with strong stability, high repeatability, easy operation and strong anti-interference ability

Model: ABHP9-C2

Size: 1200 x 1150 x 1340(mm)

Weight: 900Kg

.jpg)

Product features

1.R & D automatic intelligent digital control scanning hole coordinate touch screen LCD computer base on German CNC technology.

2.Uses Japan Tamagawa original four axis servo motor.

3.Installing trimming device to reduce trimming process.

4.The whole machine uses German import INA, AFG, DURBAL and Japan NSK, IKO and other brands of bearings.

5.Universal fixture and universal special-shaped handle box.

6.Automatic cylinder pressure, nylon rolling handle-off hopper.

7.Strong stability of the whole closed loop system, high precision of repeated positioning, easy operating, strong anti-interference ability.

Specifications of the products

.jpg)

1、Intelligent CNC Computer

.jpg)

Characteristic:1. Introducing German CNC technology to develop intelligent NC scanning hole coordinate keyboard LCD computer

2. Import CNC CPU chips from USA, speed P4 dual core

3. Automatic tracking speed regulation

4. Precise positioning and easy operation

5. The system is stable and reliable, and adapts to different environments.

6. Fully closed-loop system with strong anti-jamming ability

7. Can be upgraded to the maximum number of holes 99 (additional options)

8. Upgradable to install top and bottom hair separators (additional options)

2、Workbench and Handle-changing Servo Motor

.jpg)

Characteristic:1.X, Y-axis worktable and handle change adopt Japanese imported high precision servo motor

2. Adopt the precision C1 class double thread ball screw imported from Germany

3. Fast displacement: 820 holes per minute and jumping distance can reach 8-10mm.

4. Rigidity, flexibility, stability and reliability

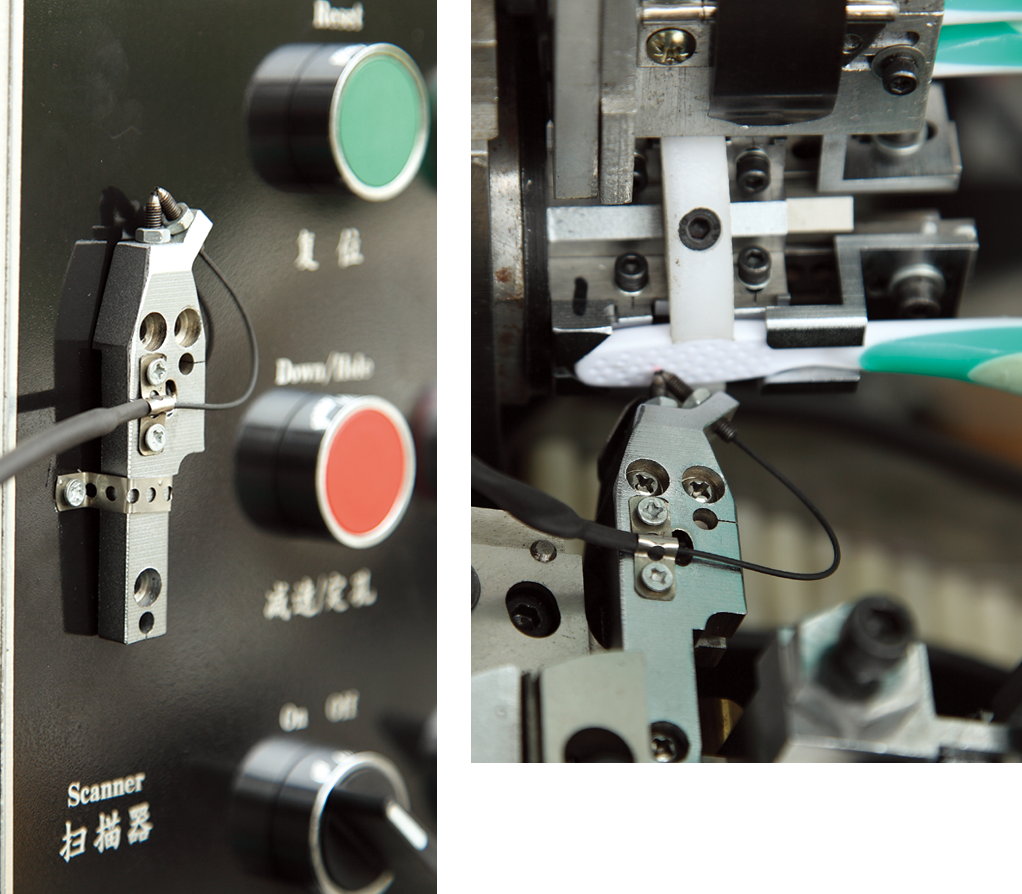

3、The coordinate part of the automatic scanning hole

Characteristic:1. Using high-tech infrared ray to automatically scan the coordinates of brush handle hole

2. Efficiency of product change: 40 holes for 5 minutes

3. High accuracy of positioning coordinates: tolerance (+0.02mm)

4. Easy to operate, fast and easy to learn

5. Reduce the tedious adjustment steps: manual measurement of hole spacing accuracy error fine-tuning

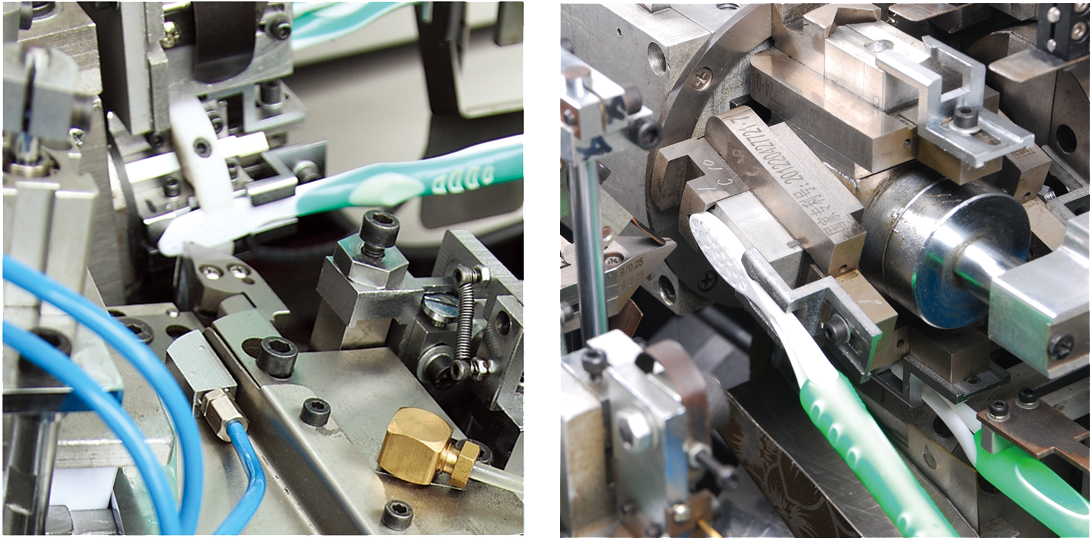

4、High Speed Growing Part

Characteristic:1. Importing German technology to develop energy fixture

2. Making wool-planting head, wool-picking knife and wool-planting rod with German imported materials

3. Growing nozzle, grooming rod, high precision mirror spark technology by imported vacuum treatment technology: high hardness, good toughness, strong wear resistance

4. The error value of high precision processing technology of wool planting machine is (+0.01 mm) and the diameter of wool planting hole is 1.2-3.0 mm.

5. Growing wool has strong stability, high efficiency, strong pulling force and no loose wool.

5、Double color wool box (ABH6-C2)

.jpg)

Characteristic:1. Applying German technology to the principle of cylinder auto-cycling action wool pressing: uniform pressure and high adjustability

2. Using double-beat wool cylinder to adjust wool neatness conveniently

3. The original Japanese servo motor is used for color change. It can support two holes for color change.

4. Using electronic wool-adding technology, easy and fast operation

5. The wool knife has high wool picking stability, non-thinning wool and non-scattering wool.

6、Tri-color wool box section (ABH9-C3)

.jpg)

Characteristic:1. The wool box adopts the German technology of split joint rotation principle: strong rotation reaction ability, small rigidity.

2. Applying the principle of pressing wool on the rodless cylinder of OGIGA in France: uniform pressure and high adjustability

3. Using three-stroke wool cylinder to adjust wool neatness conveniently

4. Using Taiwan original servo motor, high response speed can support one hole for one color.

5. Using air-controlled wool-adding technology, easy and fast operation

6. The wool knife has high wool picking stability, non-thinning wool and non-scattering wool.

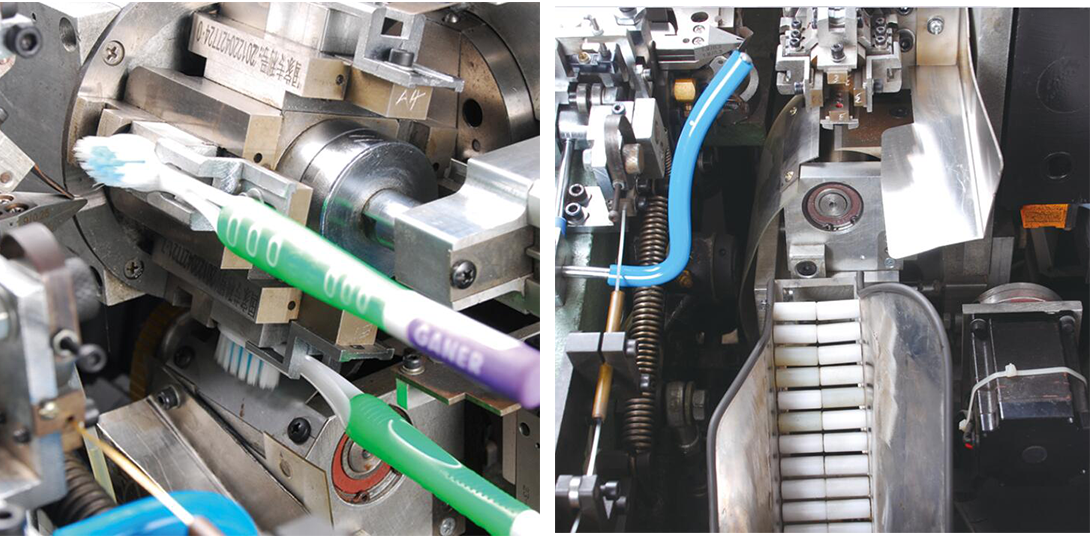

7、Nylon Rolling Handle Unloading Bucket

1. Adding decoration wool device to reduce wool trimming process

2. Easy to remove rubber brush handle